This is a Website Demo of the exact site we install for you

Custom Plastic Fabrication – Your One Stop Solution for All Projects in Plexiglass & Acrylic, and more

Custom fabrication involves turning an idea, drawing, or diagram into a tangible plastic product. It is an Important process used in industries like construction, manufacturing, retail, and the medical domain. If you’re in need of custom plexiglass fabrication for protective dividers, custom acrylic fabrication for display cases, or precise molded plastic components, a fabrication company is a must-have.

This often involves hand fabricating, cutting, welding (using special chemical bonding solvents), routing, sanding, and polishing, and requires years of experience and training to be able to deliver the highest quality that our customers have come to expect. While labor-intensive, hand fabrication is ideal for smaller quantities, quick turnaround times, and custom specifications regarding dimensions and materials. It is also ideal when finding a ready, pre-made option is not available.

In this ultimate guide, we will be covering all that you need to know about custom plastic fabrication, including benefits, materials, processes, and how you can reach the best company for your next project.

Why Is Custom Plastic Fabrication Important?

Custom plastic fabrication is the process of designing, cutting, molding, and assembling plastic components according to specific requirements. This includes techniques like CNC machining, laser cutting, thermoforming, and injection molding.

Custom Plastic Fabrication Applications

- Retail Displays: Acrylic & plexiglass displays for storefront and product showcase.

- Medical Equipment: Protective shields, sterilization trays, and enclosures.

- Industrial Components: Plastic parts used in machinery and equipment.

- Signage & Branding: Premium acrylic signage & logos.

- Architectural Features: Decorative panels, partitions, and lighting fixtures.

Custom fabrication involves turning an idea, drawing or diagram into a tangible plastic product. If you need design assistance, we are happy to help. We offer full design services.

This often involves hand fabricating, cutting, welding (using special chemical bonding solvents), routing, sanding, polishing and requires years of experience and training to be able to deliver the highest quality that our customers have come to expect. While labor intensive, hand fabrication is ideal for smaller quantities, quick turnaround times, and custom specifications regarding dimensions and materials. It is also ideal when finding a ready pre-made option is not available.

(David hand fabricating circular pedestals made from 3/8” thick clear acrylic for an event company)

Materials Used for Bespoke Plastic Fabrication

It is important to choose the appropriate material when you want the details of your product to be durable, clear, and functional. Some of the most frequently utilized plastics are:

1. Acrylic (PMMA)

- Clear, light, and shatter-resistant.

- Perfect for signs, display cases, and protective barriers.

- Comes in different colors and finishes.

2. Plexiglass

- An acrylic, commonly used as a synonym.

- Provides excellent optical clarity and UV protection

- Found in windows, aquariums, and sneeze guards.

3. Polycarbonate (PC)

- More robust than acrylic, it boasts a high resistance to impact.

- For Bulletproof Windows, bulletproof vests, and Protection Guard.

4. ABS (Acrylonitrile Butadiene Styrene)

- Strong and impact-resistant.

- Commonly found in automotive parts, enclosures, and consumer goods.

5. PVC (Polyvinyl Chloride)

- Chemical-resistant and weatherproof.

- Ideal for piping, outdoor signage, and industrial uses.

Plastic Fabrication Methods

Familiarity with fabrication methods will enable you to pick the most suitable process for your project.

1. CNC Machining

- Relies on computer-controlled machines for cutting and shaping with high accuracy.

- Excellent for intricate designs and high-precision components.

2. Laser Cutting & Engraving

- Offers accurate cuts for complex shapes.

- Solid printing coroplast: Commonly used for signage, branding, and decorative panels.

3. Thermoforming

- Heating plastic sheets and shaping them.

- Used in packaging, enclosures, and automotive parts.

4. Injection Molding

- Ideal for high-volume plastic parts production.

- Creates long-lasting and reliable parts.

5. Vacuum Forming

- Uses suction to shape heated plastic over a mold.

- Economical for light, large workpieces.

Advantages of Custom Plastic Fabrication

There are multiple benefits that come with using custom plastic fabrication for your projects

1. Economically Constructive

- In comparison to metal fabrication, the material and manufacturing expense is considerably lower.

- Trims and molds accurately, minimizing waste.

2. Lightweight & Durable

- Acrylic and polycarbonate will be much lighter than glass or metal.

- Provides great strength and impact resistance.

3. Versatility in Design

- Custom fabrication allows for intricate and unique designs.

- Comes in multiple colors, finishes, and transparency levels.

4. Weather & Chemical Resistance

- Great for outdoor usage, medical setups, and industrial environments.

5. Environmentally Friendly Choices

- Most plastics can be reused and recycled.

Choosing the Right Custom Plastic Fabrication Company

Choosing the right fabrication partner will not only ensure high-quality results but also ensure your project is completed efficiently and timely manner. Be sure to consider the following:

1. Experience & Expertise

- Seek companies that will be able to demonstrate an extensive background in plastic fabrication.

- Look for past projects in their portfolio that are similar to yours.

2. Services Offered

- Check if they provide a variety of fabrication methods (CNC, laser cutting, molding, etc.)

- Ability to customize designs.

3. Choice of materials

- The company should provide different types of plastic materials.

- Can recommend the best material for your project.

4. Quality assurance

- Certification and compliance with industry standards.

- Testimonials and reviews from customers.

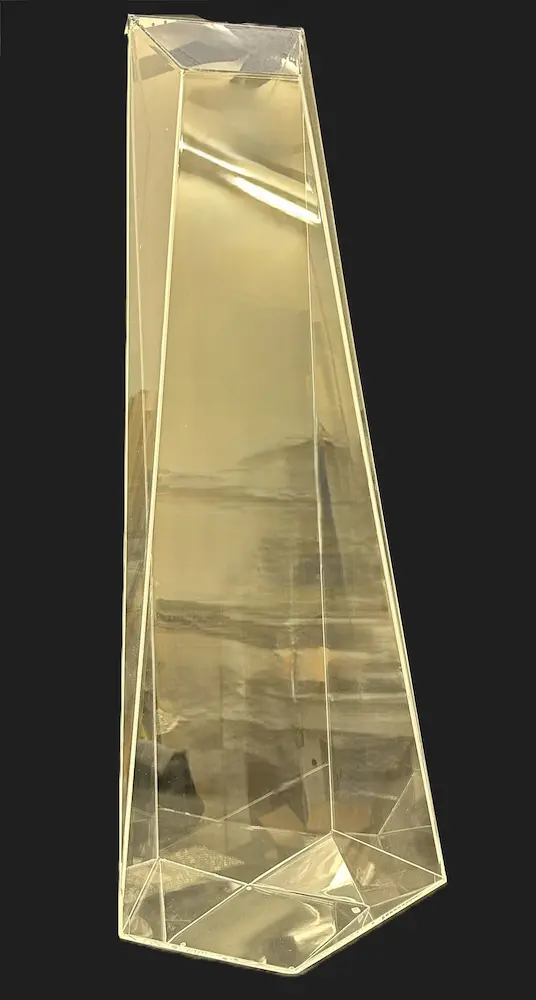

(Custom hand fabrication of a unique sculptural piece made from ¼” clear acrylic)

(Custom fabricated donut walls ordered by Fontaine Bleau Las Vegas)

We were honored to have been selected to replace these 20 large acrylic tubes at The Shops at Crystals in Las Vegas

Conclusion

Custom plastic fabrication can provide you with a wide range of options for creating your project using a variety of plastics with high strength-to-weight ratios, using durable and visually appealing materials.

Looking For A Quote For Custom Plastic Fabrication?

Contact us at (702) 240 - 9668 or fill out our contact us page for a free consultation and find the perfect solution for your project!

Start A Conversation

Contact us today for a no obligation quote

Where innovation meets durability – We at Welch Plastics continuously offer high-quality, precision plastic fabrication to transform your ideas into reality. Reach out to see what we can create for you.

Since 2000

Welch Plastics

Where innovation meets durability – We at Welch Plastics continuously offer high-quality, precision plastic fabrication to transform your ideas into reality.