This is a Website Demo of the exact site we install for you

Plastic Sheets: Flexible and Durable Applications

Plastic sheets are an integral part of manufacturing, construction, and product design. Plastic sheets are strong, flexible, and inexpensive. They are used for everything from point-of-purchase retail displays to protective medical equipment. Welch Plastics specializes in custom plastic fabrication, custom plastic sheet material solutions that accommodate your exact specifications as an architect, engineer, manufacturer, or product designer.

As a qualified plastic manufacturer in Las Vegas, we offer full sheet size, cut-to-size sheets, or fabricating fabricated parts that match your specifications. In this guide, we will go through what types of plastic sheets are in the market in 2025, the applications & benefits, and finally determine the best plastic material for your project.

What are Plastic Sheets?

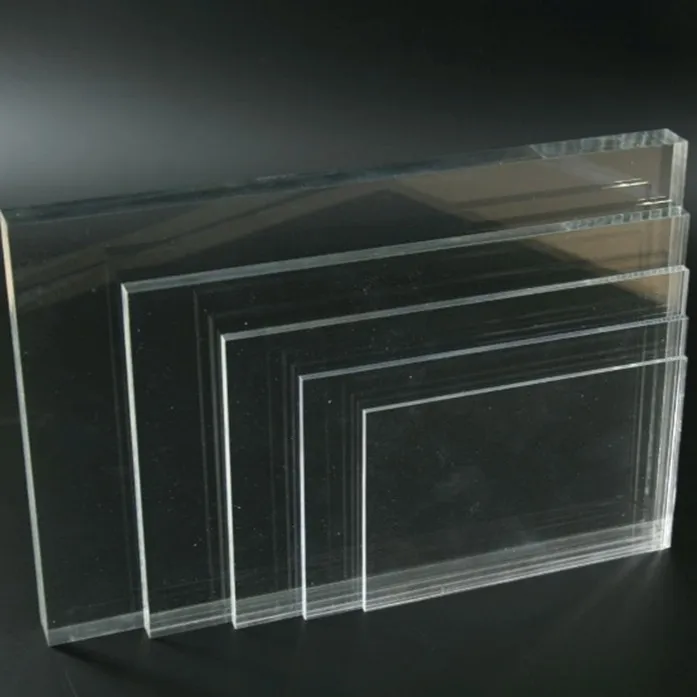

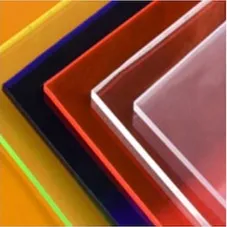

Plastic sheets are flat, semi-flexible (thermoplastic), semi-rigid (thermoplastic), or rigid (thermoset) panels made from a thermoplastic material. There is a long list of plastic sheets made from various materials, sizes, thicknesses (most commonly from 0.5mm to 50mm+), colors, finishes, and material types. Plastic sheets can be cut, machined, thermoformed, bent, bonded, printed, etc. Plastic sheets are useful in many industries and applications.

Welch Plastics provides plastic manufacturing services, either off-the-shelf plastic materials or totally custom-made plastic parts using CNC routing, laser cutting, and thermoforming.

Types of Plastic Sheets and Their Applications

It is essential to understand the many different types of plastic sheets and their properties enough to match the material to your application. Below is a summary of the most common types of plastic sheets:

| Material | Characteristics (What to consider) | Uses (What to make) |

| Acrylic (PMMA) | Light, UV resistant, high optical clarity | Signage/Aquariums/Sky lights |

| Polycarbonate | Impact resistant, heat tolerant | Machine guards/Windows/Roofs |

| ABS | Tough, machinable, matte surface | Automotive trim/Enclosures/3D Printing |

| PVC (Rigid & Foamed) | Flame retardant and easily fabricated | Displays/Wall Panels/Signs |

| HDPE (High-Density Polyethylene) | Chemical and moisture resistant | Cutting boards/Tanks/Piping |

| PETG | FDA compliant, clear, flexible | Food packaging/Retail displays |

| Polypropylene | Lightweight and fatigue resistant | Chemical tanks/Food Tubs |

| HIPS | Cost-effective and printable, and thermoformable | Packaging/Point-of-purchase displays |

| UHMW-PE (Ultra High Molecular Weight Polyethylene) | Low friction/self-lubricating | Conveyor systems/Marine parts |

If you work in medical or food processing areas, find your custom plastic sheet product solution at Welch Plastics, where we provide custom plastic fabrication with professional service.

Benefits of Using Plastic Sheets Over Other Products

There are many benefits to using plastic sheet products, rather than other materials, like wood, metal, or glass, and here are a few of them:

1. Lightweight but Durable

Plastic sheet products have an exceptional strength-to-weight ratio; therefore, they are ideally suited for portable, structural, and industrial applications without compromising quality and performance.

2. Chemical & Moisture Resistant

Plastic materials (like HDPE and polypropylene) are naturally resistant to chemicals and moisture that are important in medical, marine, and industrial applications.

3. Custom Fabricated Ability

Plastic sheets are extremely workable, we offer CNC machining, laser etching, bending, bonding, and vacuum forming gives the chance to meet varying design specifications.

4. Low Maintenance

Plastic sheets require less maintenance than wood and metal; they are stain resistant, they don't rust, and we don't have to paint or seal them.

5. Cost-effective:

Plastic sheet materials are generally less expensive to produce, install, and maintain, so they're a good choice for cost-sensitive or high-volume projects.

6. UV and Weather Resistant:

Some plastics are UV stabilized (like acrylics and polycarbonates) and can be used in outdoor applications like signage, roofing, and window glazing.

Common Usage of Plastic Sheets in Various Industries:

The usage of plastic sheets spans many industries, including healthcare, food processing, automotive, marine, and architecture. Here are some applications:

🔹Signage & Displays:

- Illuminated signs

- Directional signs

- Backlit diffusers

- Retail point-of-purchase displays

🔹Construction & Architecture:

- Wall partitions

- Protective barriers

- Window glazing replacement

- Decorative wall panels

🔹Automotive & Transportation:

- Dashboards and door panels

- Underbody guards

- Custom interiors and storage

🔹Medical & Cleanroom Environments:

- Sneeze guards

- Sterile trays

- Lab enclosures and lab instruments

🔹Food Processing & Packaging:

- FDA-approved cutting boards made from HDPE

- Vacuum-formed clamshell packaging (fast-food packaging)

- Custom packaging trays

🔹Marine & Outdoor Products:

- Boat windows and panels

- Sunlight and UV-resistant barriers

- Dock components

🔹Industrial & Manufacturing:

- Equipment housings and enclosures

- Machine guards

- Storage bins and sorting trays

Choosing The Right Plastic Sheet Material:

With so many options available, how do you know which sheet is right for you? Think about these key factors below:

| Requirement | Recommended Material |

| Optical clarity or color | ACRYLIC, PETG, POLYCARBONATE |

| High-impact Resistance | Polycarbonate, ABS |

| Chemical Exposure | HDPE, Polypropylene |

| Thermoforming required | PETG, HIPS, ABS |

| Food Grade Compliance | HDPE, PETG, Polypropylene |

| Weather resistant | U.V. stabilized for Acrylic or Polycarbonate |

Still lost? The team at Welch Plastics can assist you with the best fit with a free consulting visit and/or with custom samples.

Why is Welch Plastics the best choice for your plastic sheet supplier?

With all the manufacturers of plastic products available, why choose Welch Plastics? Welch Plastics is a leading plastic manufacturer based in Las Vegas. With 30 years of overall experience and independence, we are proud to manufacture and specialize in custom plastic fabrication.

Here’s why companies across the United States choose Welch Plastics for their plastics needs:

-

Quality raw materials

All of our plastics are sourced from leading national distributors that guarantee the strength, style, and durability of their plastic sheet.

-

Custom fabrication services

Our fabrication shop can laser cut, CNC route, assemble multiple products, and integrate complex parts with injection molding, all with tolerances to your specifications.

-

Quick turnaround and bulk quotes

Welch Plastics has a very extensive inventory of materials that can be shipped for immediate service. Whether you are ordering one sheet or one thousand sheets, we can ship when you need it and with competitive pricing.

-

Shipping across the USA

Welch Plastics is based in Las Vegas and can easily ship products to customers across the USA. Need sheets custom-cut in less than 3 days? No problem!

-

Design and material development

Our unique plastics experience spans over decades. We work with plastics in all of their forms and can help you design, source, and manufacture your plastic component from start to finish.

Frequently Asked Questions (FAQ):

-

Q: What thickness encapsulations do you have?

A: We have sheets available in thicknesses as thin as 0.5 mm (0.02”) extending to over 50 mm (2”), depending on the plastic material. We can also accommodate custom thicknesses upon request, including oversized.

-

Q: Do you cut custom shapes?

A: Yes! Our fab shop is equipped with CNC routers, laser cutters, and saws that can cut to your required specifications.

-

Q: Are your plastic sheets UV stable?

A: Some materials, like acrylic and polycarbonate, are UV stabilized and have weather resistance. Please let us know what your application will be, and we will recommend an appropriate option.

-

Q: Do you offer quantity discounts?

A: Yes! We will negotiate wholesale pricing for large-scale pricing or ongoing contract pricing. Please call us for a specific quote.

-

Q: Are your plastic sheets recyclable?

A: Yes. Materials like HDPE, PETG, and acrylics are recyclable. We try to be environmentally responsible in our processes and reuse our waste in our manufacturing.

Request a Free Quote for Custom Plastic Sheets!

If you want to order quality plastic sheets, speedy turnaround, and knowledgeable help, then Welch Plastics is your best option. We can assist you with getting simple cut-to-size sheets, CNC-machined parts to exact specifications, to a supply partner for repeat injection molding and plastic fabrication.

Let's discuss your wants, your expectations, and how we can help support you!

📞Call (702) 240-9668

📧Email info@welchplastics.com

Let Welch Plastics make your vision into the finished solution you need - all with 20 years of trade experience, speedy turnaround delivery service, and a national reputation in custom plastic fabrication.

Sheet Material

We carry a wide range of sheet material: acrylic (plexiglass), polycarbonate (lexan), HDPE, ABS, PETG, EPVC available for full sheet order as well as cut to size. Standard material size is 48” x 96”

We are able to source any type of sheet material as well as oversized material. For bulk orders, minimum order quantities may apply. Contact us for more details.

Plastic Tube

We are able to source at very competitive prices hard to find large plastic tube. If you have ever tried to find plastic tube in diameters of 12” or more, you know how scarce they are and what a premium suppliers charge for them.

Diameters available for special order from 12” up to 18” and from 1/8” thickness up to 1” thick side walls. Minimum length of 48” up to 100”. Minimum order quantities may apply. Typical lead time for large plastic tube is 3-7 weeks. Contact us for more details.

Start A Conversation

Contact us today for a no obligation quote

Where innovation meets durability – We at Welch Plastics continuously offer high-quality, precision plastic fabrication to transform your ideas into reality. Reach out to see what we can create for you.

Since 2000

Welch Plastics

Where innovation meets durability – We at Welch Plastics continuously offer high-quality, precision plastic fabrication to transform your ideas into reality.